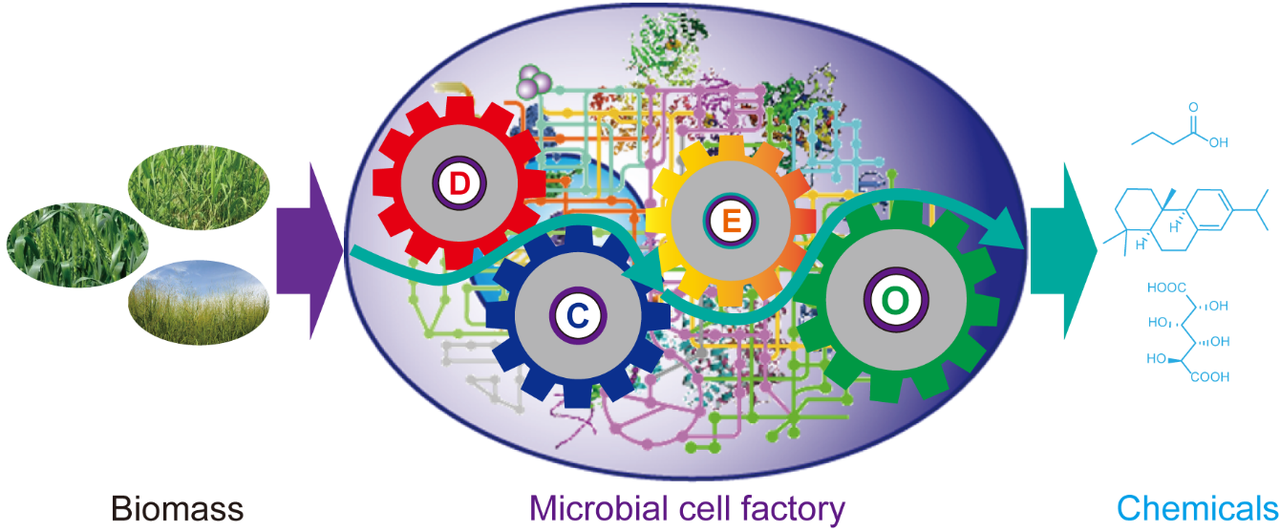

Developing sustainable processes for fuels, chemicals, and materials production is necessary to develop a fossil fuel-independent society [1]. Microbial cell factories offer an alternative strategy to produce valuable chemicals, including biofuels, chemicals, and pharmaceuticals from renewable feedstock [2]. However, microbes have evolved exquisite regulatory control mechanisms to limit the three pillars of microbial cell factories, namely the titre, yield, and rate. To implement more sustainable processes in industry, a high efficiency of microbial biocatalytic systems for the production of industrial chemicals from renewable feedstocks is important. To this end, traditional strain breeding [3] and rational metabolic engineering [4] strategies have been developed. Liu et al. have provided a conceptual and technological framework (DCEO Biotechnology) to manipulate microbial cell factories in order to enhance the metabolic capabilities of industrial strains [5]. In fact, the efficiency of the microbial cell factory is determined by its metabolic capabilities, physiological state, and environmental conditions.

Aging is a progressive morphological and functional change that disturbs the ability of cells to maintain homeostasis and increases the probability of death. Aging, including replicative and chronological aging, is a general characteristic of bacterial strains. According to this classification, the lifespan of an Escherichia coli strain can be divided into its replicative lifespan (RLS) and chronological lifespan (CLS). As important physiological parameters, CLS and RLS could be manipulated as a potential strategy to regulate the physiological state of microbial cells. Thus, engineering lifespan provides a potential opportunity for enhancing microbial cell factory performance.

Recently, Liu et al. described how engineering the lifespan of Escherichia coli presents a platform technology for improving the bioproduction of chemicals. In this study, the lifespan of an industrial strain of Escherichia coli was modulated by genetic manipulation. The cell size of Escherichia coli was enlarged to enhance poly(lactate-co-3-hydroxybutyrate) (PLH) production by engineering the RLS via a two-output recombinase-based state machine (TRSM) (Fig. 1). Additionally, the CLS of Escherichia coli was engineered to increase butyrate production via a multi-output recombinase-based state machine (MRSM) (Fig. 1). As a result, the highest content of PLH (52 wt%) and the highest titer of butyrate (29.8 g/L) were achieved in a 5-L fermenter. Escherichia coli strains with engineered lifespans exhibited superior applicability for increasing chemical production via a microbial cell factory. Despite millions of years of evolution, the Escherichia coli lifespan is remarkably plastic, and manipulation of this cellular characteristic is expected to advance both metabolic engineering and synthetic biology.

Fig. 1 Engineering Escherichia coli lifespan for enhancing chemical production. The RLS was fine-tuned using a two-output recombinase-based state machine to enlarge space for more poly(lactate-co-3-hydroxybutyrate) (inclusion body) accumulation. The CLS was modulated through a multi-output recombinase-based state machine to enhance butyrate production.

References:

1. Dai, Z. & Nielsen, J. Advancing metabolic engineering through systems biology of industrial microorganisms. Curr Opin Biotech 36, 8-15 (2015).

2. Nielsen, J. & Keasling, J.D. Engineering cellular metabolism. Cell 164, 1185-1197 (2016).

3. Wang, X., Zhang, H. & Quinn, P.J. Production of L-valine from metabolically engineered Corynebacterium glutamicum. Appl. Microbiol. Biotechnol. 102, 4319-4330 (2018).

4. Park, J.H. & Lee, S.Y. Towards systems metabolic engineering of microorganisms for amino acid production. Curr. Opin. Biotechnol. 19, 454-460 (2008).

5. Chen, X.L. et al. DCEO Biotechnology: tools to design, construct, evaluate, and optimize the metabolic pathway for biosynthesis of chemicals. Chemical Reviews 118, 4-72 (2018).

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in